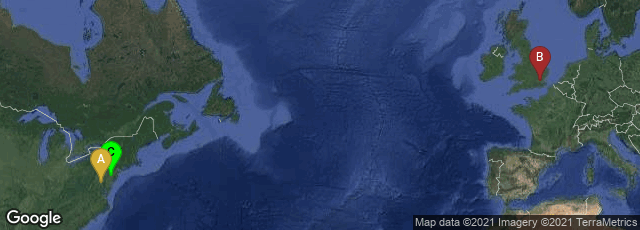

A: Washington, District of Columbia, United States, B: London, England, United Kingdom, C: Philadelphia, Pennsylvania, United States

"Tolbert Lanston and the Monotype". Painting by Robert Thom in the series Graphic Communications Through the Ages preserved in the Cary Graphic Arts Collection, Rochester Institute of Technology.

In 1887 American inventor Tolbert Lanston of Washington, D.C. demonstrated his prototype of the Monotype machine, a machine that set individual characters of type in justified lines rather than "lines of type" like the Linotype machine. Lanston's initial typesetting machine consisted of a keyboard producing a perforated record of a job in a paper spool, something like a player piano roll, which controlled an associated machine for fashioning types from cold strips of metal with 196 matrices.

The concept of driving a typesetting machine from punched paper, similar to Jacquard cards, had originally been patented by William Martin as early as 1849, and had been improved by Alexander Mackie in 1867, but there was little demand for mechanized typesetting at that time, and, perhaps more importantly, neither of those machines were sufficiently functional to become established in the typesetting community. To produce his new machine Lanston originally founded the Lanston Type Machine Company in Virginia on November 13, 1886.

"The perforated tapes, of which he employed two, caused a strip of type metal to be fed into a compression box and the proper die to be centered above it, a section of the type metal cut off and compressed to form the type, which was then ejected on to the gallery, the entire operation of the typemaking machine being automatic. Justification was provided for on a novel principle. A scale indicated to the operator of the perforating mechanism on completion of a line the amount of space yet unfilled and the perecentage which this bore to the filled space, he thereupon striking certain keys to cause perforations to be made at the end of the line. The tape was fed backward through the automatic typemaking machine and these last perforations caused the body of each letter in the line, or, if desired, only the spaces therein, to be increased above the normal such a percentage as to produce a line of justified type. In this machine electromagnets were employed to control the mechanism" (Thompson, History of Composing Machines [1904] 120-21).

Notably Lanston demonstrated his machine three years after Mergenthaler invented the Linotype, and one year after the Linotype was usefully applied to production of the New York Daily Tribune newspaper.

Both Lanston's U.S. and British patents are dated June 7, 1887. The British patent specification No. 8183, Improvements in the Art of Printing, in my collection makes 64 claims with respect to a mechanism for line justification and a method of type forming. It consists of 29 pages of text and 9 diagrams, of which 8 are double-page.

Lanston's statement begins:

"While astonishing progress has been made in those branches of the art of printing which relate to the taking of impressions and to the folding and delivery of the matter printed, but comparatively little practical advance has been made in that department which relates particularly to the setting up and justification of the lines from which the impressions are to be taken.

"Type setting machines of more or less efficiency it is true have been employed to assemble the types but, even where such machines have been successfully used it has always been found necessary to subject each line of composition to a process of justification involving, usually the introduction of suitable mechanism, or by hand, of additional spaces, or of the substitution of wide or narrow spaces, and vice versa, much the same as in the case of matter set up by hand.

"Machines have also been constructed with a view to the production of solid lines of justified composition, even in such machines the justification of the line is only secured by justifying the dies or molds which produce them and this justifying operation is performed in the ordinary manner, above referred to.

"My invention is a wide departure from the previous methods and proceeds upon a principle, which I believe to be radically new. Instead of producing a line of composition and then justifying it I form my types for a given line in such manner as to cause them when assembled, to form a complete justified line ready for printing direct or for making an impression for stereotype or electrotype purposes without further manipulation.

"In attempting to surplant by machinery the ancient process of setting type by hand the advantages to be derived from copying as many of the conditions of such hand set type as possible as [sic; should be "are"] manifest. By so doing, the mechanical products will be in harmony with all the other conditions of the art of printing as now practiced, will involve no departure from its usages and will permit the same method of correction of errors, interpolations, shifting of matter &c. as are now in vogue. It is well known that in ordinary composition where common type is used it rarely ever exactly fills a line of given length, the rule being that a space of greater or less length is left at the end of the line which must be filled up or absorbed in the process of justification. Now, since it is apparent that in every case this unoccupied space at the end of the line must bear a certain relation to the part of the line filled by the characters or in other words, represent a certain percentage of the combined width of such characters, it follows, that if there be added to the normal width of the body of each of the assembled types a percentage of increase, corresponding to the percentage which said unoccupied space represents to the occupied space, the line composed of types so formed will be rendered self justifying. . . . "(pp. 1-2).

To develop his invention Lanston moved his business to Philadelphia where he formed the Lanston Monotype Company. As the technology progressed this company became known as the Lanston Monotype Machine Company. In 1890 Lanston abandoned the concept of stamping letter shapes into cold metal and introduced casting techniques. Within a year he had developed a version of this idea called the "Hot-Metal Machine." For this he obtained US Patent 557994, granted in 1896.

According to the best book on the history of American Monotype, Hopkins, Tolbert Lanston and the Monotype. The Origin of Digital Typesetting (2012), the first published article on the Monotype machine appeared in Paper and Press Illustrated Monthly in September, 1891. This article I have not seen. Before that the company published in New York in 1889 a pamphlet entitled The Lanston Type-Machine. Expert Report of Coleman Sellers, and Church & Church and W.W. Gordon. This pamphlet, surviving perhaps in only one copy, previously in the Franklin Institute, and now preserved in the Getty Research Institute, provides the earliest technical description of the operation of the machine, including examples of actual typesetting. It was published as a promotional effort to raise money for development of the company.

The first typeface issued by the Lanston Monotype Machine Company in the USA was Modern Condensed (Series 1) in 1896.

"It was made for the Model C Keyboard which mirrored the layout of the die-case on the caster. That is, the narrow characters occupied designated rows, as did the wider characters. Effectively the character widths allocated were imposed uniformly on all early designs. To do otherwise would have meant a different keyboard layout for each typeface."

By 1897 American mechanical engineer John Sellers Bancroft converted the Monotype into a casting apparatus that was controlled from a perforated paper job record. This required reducing the number of available typographic characters from 225 to 132, thereby becoming known as the "Limited Font Machine." Also, a justification wedge was perfected for expanding word spaces, instead of adding space to every character in a line. These enhancements represented the beginning of the "modern" Monotype system.

Running short of funds, J. Maury Dove and Harold M. Duncan of the Lanston Monotype Machine Company decided to raise money by taking four of the Limited Font Machines to London for demonstrations. On the Atlantic crossing the two Americans encountered Lord Dunraven, who bought the British and Colonial (except Canada) patent rights to the Monotype system for £220,000: the equivalent of one million dollars at the time. This enabled William Sellers & Co. to continue efforts to improve the caster.

Dunraven founded Lanston Monotype Corporation Ltd in London, later known as Monotype Corporation. Two years later, in 1897 John Sellers Bancroft re-engineered the Monotype caster to restore the character component to the originally intended 225. The American and English companies developed independently and each developed many notable and enduring type fonts.

(This entry was last revised in 6-23.)